Basics of Turning

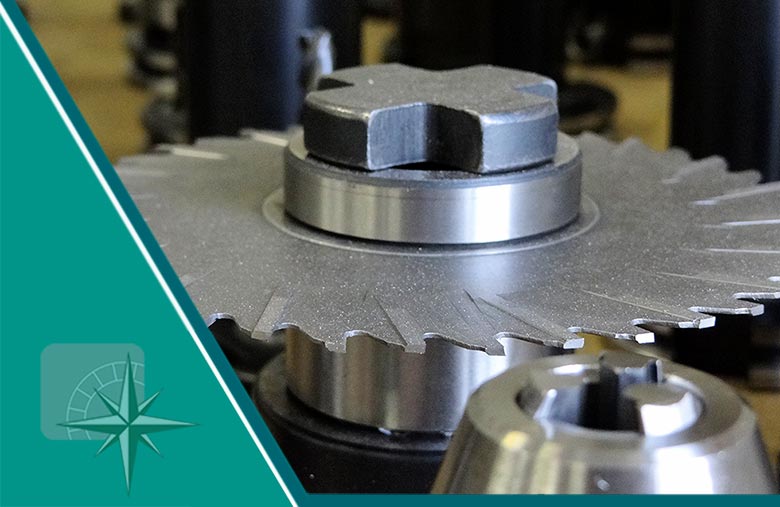

Description

This introductory course will cover the basic concepts of turning, from the definition of turning and its basic tools, to advanced techniques for shaping metals and producing complex shapes. Participants will learn how to set up and adjust the machines.

What Will I Learn?

- Basic Turning Review: Understanding lathe concepts and types.

- Hand Tool Proficiency: Familiarity with basic hand tools.

- Safety Awareness: Knowledge of safety controls and clothing.

- Maintenance Skills: Ability to perform regular machine and tool maintenance.

- Measuring Tool Training: Proficiency in using vernier calipers and micrometers.

- Workpiece Installation: Skills in installing various workpieces.

- Lathe Operations: Competence in external and internal lathing, carving, beveling, and threading.

- Machine Preparation: Skills in preparing the lathe, selecting tools, and determining speeds.

- Lathing Application: Experience in applying lathe operations and maintaining the machine.

- Practical Production: Ability to produce parts and control dimensions accurately.

- Finishing Techniques: Skills in trimming, polishing, and enhancing workpieces.