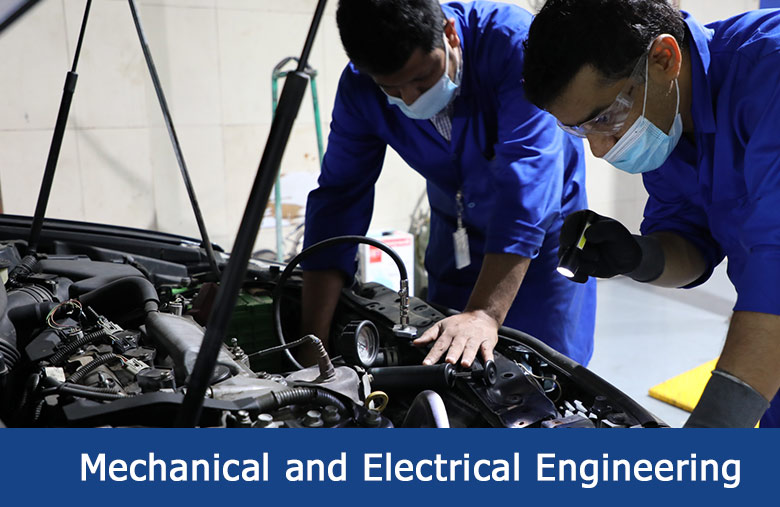

Based on the role of Lootah Technical Center and the training and rehabilitation programs it provides for all sectors, and believing in the center’s important role in refining the trainees’ skills. The center announces the launch of the “Professional Diplomas” program, which is considered one of the best training programs because it qualifies you to join the labor market. The program starts on Wednesday, 01/09/2021 AD. Hurry up and join the professional diploma programs. Seats are limited… For reservations and inquiries: 971563587346 / 042125333

Search for Your Course

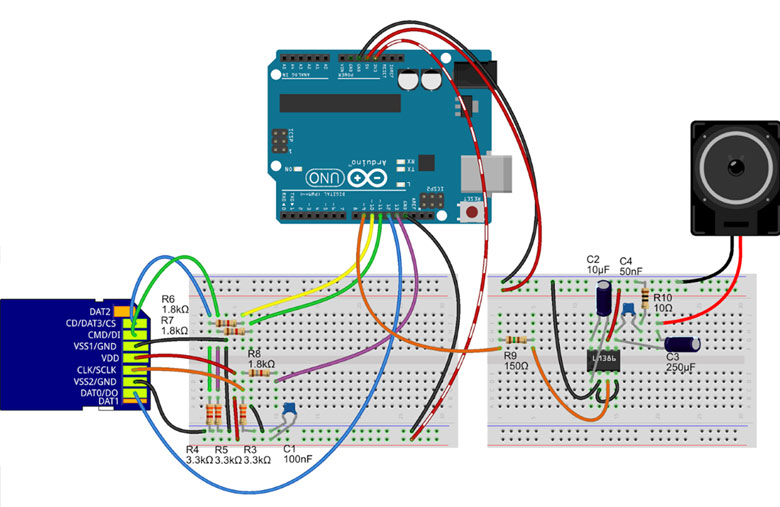

Advanced Technology Courses

Trainings

Partners

Clients